In this section we have compiled a group of featured

products that have either garnered a significant amount of

interest or currently are on special. We feel that

this assortment of products and solutions will provide great

value and benefit to your process. When we assembled

our line of products, services and solutions we kept quality

as our first priority. You will see this reflected in

the assortment of products that we carry, and keep in mind

we are not a catalog house. We sell what we believe in

and we believe in what we sell. We don't stock a

million flavors, but rather a selection of high quality and

valuable solutions.

We have categorized the products

once again by category to make it easier to find a solution

for your process needs. You can also use the

"BOOKMARKS" to quickly access information you may require.

If you have a sales question, please feel free to contact us at:

sales@ntech-inc.com

KYZEN

A4241

A4625B

AQUEOUS TECHNOLOGIES

TRIDENT

ZERO-ION

RINSE WATER RECYCLER (RWR)

KURTZ ERSA

i-Con 1

SAMSUNG

Samsung YouTube Videos

EXCEN PRO

SM SERIES

SMT FEEDERS

Kyzen's A4241 chemistry is a versatile aqueous chemistry that is capable of both PCB defluxing and stencil cleaning. The Kyzen A4241 provides superb cleaning abilities and bright, shiny solder joints on your PCBs.

Booster20 is an inhibitor used in combination with the Kyzen A4625B

cleaning chemistry. Booster20 is added sump side (meaning when the chemistry is

poured into the cleaning system, as compared to being packaged in the chemistry

itself prior to addition) to the wash solution. Unfortunately, due to the

separating characteristic of the Booster20, it cannot be packaged into the

chemistry,

This additive is required when cleaning Leaded (Pb) alloys, if

unused, you will observe darkened solder joints.

Clicking on the

HTML icon will provide you data based upon a 15% concentration, whereas clicking

on the Excel link will provide you with an Excel Spreadsheet.

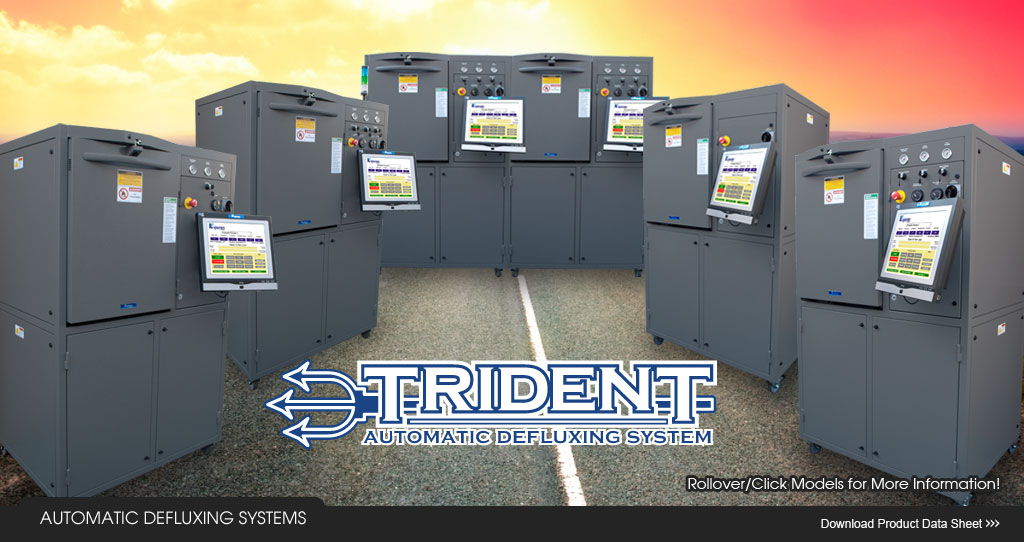

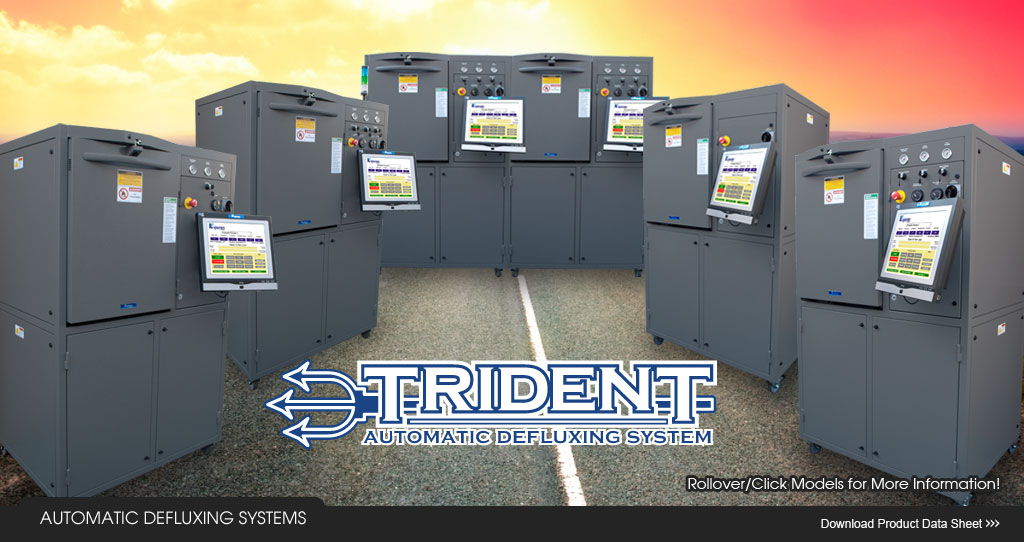

Aqueous Technologies - Trident Defluxing System

A

batch defluxing process is much more efficient than running an inline defluxing

process, especially in an Aqueous Technologies Trident Defluxing System.

First, a batch defluxer is heating up a much smaller quantity of wash

solution (approx. 3.5 gallons) for use in the wash process; whereas, in an

inline cleaning system you are trying to heat 60 gallons of wash solution.

The difference in energy usage is quite significant in comparison.

Secondly, the separation of wash process to rinse process is

a difficult task. The only effective methods are to increase the footprint

of the machine by elongating the line and creation of an chemical isolation zone

or to accurately place and tune your spray jets to ensure less carry over from

one zone to the other.

The problem is if rinse water makes it into

your wash solution tank, your wash solution concentration will decrease and

cleanliness issues could arise. On the opposite, if too much wash solution

chemistry is making it to the rinse zone, you are washing valuable chemistry

down the drain.

A batch defluxing system, like the Trident, completely

separates the wash process from the rinse process by using separate plumbing for

both process. When the wash process is complete, the Trident returns the

wash solution to a holding tank and actuates a series of solenoids to activate

the rinse process, at which time it brings in fresh DI water to rinse the

PCBs/PCAs. Very minimal amounts of chemistry are wasted, usually the form

of suds on the chambers or PCBs that doesn't return to the wash solution tank,

this is considered your dragout.

We have compiled some data that helps

you to assess what the cost of a cleaning process, you can view this information

by clicking on the HTML icon below. This is an estimated cost per batch,

so remember the more PCBs that can be loaded, means a more efficient process.

Aqueous Technologies - Zero-Ion Cleanliness Tester

Once you have cleaned your PCBs of any soils, fluxes, residues, or residual

cleaning chemistries, it is important to determine the cleanliness of your PCBs.

This allows you to benchmark your cleaning process and observe any changes in

your processes (cleaning, assembly, wave or reflow) by auditing your production

units and observing any change in cleanliness.

The Zero-Ion system is a

R.O.S.E (Resistivity Of Solvent Extract) tester that uses an IPA (Isopropyl

Alcohol)/DI Water solution to extract any soils or contaminents that may remain

on the PCB after the cleaning process. The system then calculates based

upon your PCB size and gives you PASS/FAIL results with data based on inudstry

standards for PCB cleanliness.

The Zero-Ion is very effective at sensing

contaminations on the PCBs which leads to a very high level of accuracy in

assuring that your PCB defluxing process is performing to the levels that want

to achieve.

Aqueous Technologies - Rinse Water Recycler

Making

your process "Green" will incur an added cost, when comparing to going

straight to drain. Assessing what those costs will be is key in your

decision of Rinse Water Recycling vs Evaporation. Also, please consider

that evaporation is still exhausting into your environment, but through a vent

stack as compared to a drain. This is a key point in regards to the impact

on your environment, plus it is something that can surely be regulated in the

future, which will cause you to reassess your process again. In fact,

Aqueous Technologies has discontinued the E101 evaporator as the industry moves

definitively in favor of the Rinse Water Recycler.

In our

experience, Rinse Water Recycling is the best solution. As you will find

the operational costs (media tank exchange) are actually minimal, when you

compare to the operational costs (electricity) involved with the evaporation

process. Not to mention an evaporation process isn't truly green

considering it is still exhausting to the vent and it is using large amounts of

energy to evaporate the drain water.

- Clicking on the PowerPoint icon

will allow you to open or save a PowerPoint presentation of data that we

collected comparing the operational costs of both processes.

-

Clicking on the PDF icon will open a PDF version of the same presentation.

- Clicking on the HTML icon will open up an HTML representation of the data

viewable in your browser

Ersa i-Con Hand Soldering Station

![]()

![]()

![]()

![]()

The

Ersa i-Con 1 Hand Soldering system is a state of the art soldering iron system

that gives you the ultimate controls of your hand soldering process. The

engineering of the system takes several factors in account, including:

conveniencem, quality and efficiency.

The i-Con 1 uses accuracte

thermocouple placement and 150w heating element to provide you with an accurate

hand soldering tool that has sufficient power to quickly recover andythermal

energy that is transferred to the solder joint in the hand soldering process.

This allows you to solder at lower temperatures, rather than compensating

with increased temperatures. This is safer for both your tips and your

components. Lower temperatures can greatly prolong your tip life, which

can save you significant amounts over the life of the soldering stations.

Furthermore, the Ersa i-Con 1 uses i-Tips which have about 2-3 times the

plating of most of our competition. The Ersa i-Tips use approximately

300-600µ of Iron (Fe) plating, in comparison to approximately 100-200µ

of Iron (Fe) plating in our competitors'. This simply means that our tips

will last approximately 2-3 times as long, under the same conditions (time,

temp, etc.); which with the added efficiency of the Ersa i-Con 1 only works

further in Ersa's favor.

Often, the operational costs of a soldering

station are overlooked because a company is already invested in a station.

But we ask you to take a look at the actual costs of your current soldering iron

stations, not what they originally cost you, but what are they costing you now

to keep them in operation?

By clicking on the HTML link you will get a

representation on the potential savings based upon 15 stations.

By

clicking on the EXCEL link you will be able to save and manipulate the data to

your application.

Samsung SMT Placement Equipment

SAMSUNG EXCEN:

http://www.youtube.com/watch?v=_qyqxn96amY

SAMSUNG SM471/481/482:

http://www.youtube.com/watch?v=GFpcrTCEapE

SAMSUNG F.A.S.T. feeder technology:

http://www.youtube.com/watch?v=3vzunE5vkCM

|

|

| SP1 Series | EXCEN PRO |

| BROCHURE | |

|

Accuracy: 12.5 µm at 6σ |

120,000 CPH Optimum |

|

Print Cycle Time: 5 seconds (excluding print time) |

4 Gantries |

|

16 Head Turret |

|

|

Stencil Size (mm) |

0402 Metric |

|

Applicable PCB Size (mm) |

Max PCB Size (mm) |

Samsung's new

EXCEN PRO system is an Ultra-High Speed SMT Placement system that

allows for a very high throughput, without sacrificing your physical footprint.

The EXCEN PRO system combined with the SP1 Series

Solder Paste Printer allows you to maximize your placement throughput and keep

up with the high volume demands of your application.

The EXCEN

PRO system delivers optimum placement speeds of up to 120,000 CPH!

The system achieves this with a dual rail, 4 gantry system with 16 head turrets

on each gantry. The system can be assembling 4 board assemblies at one

time.

If you have a high volume application, the EXCEN PRO

is a very capable solution for your process!

|

|

|

| SM471 | SM481 | SM482 |

| BROCHURE | BROCHURE | BROCHURE |

| 75,000 CPH Optimum | 39,000 CPH Optimum | 28,000 CPH Optimum |

| 2 Gantries | 1 Gantry | 1 Gantry |

| 10 Spindles/Head | 10 Spindles/Head | 6 Spindles/Head |

|

0402 Metric 01005 Imperial |

0402 Metric 01005 Imperial |

0603 Metric 0201 Imperial |

|

Max PCB Size (mm) |

Max PCB Size (mm) |

Max PCB Size (mm) |

Samsung offers more

than just high speed solutions, they also offer systems that allow for more

flexibility, combinations of speed and flexibility and also systems configured

for limted budget applications.

The SM Series of placement equipment

offers 3 main configurations of systems allowing placement speeds ranging from

28,000-75,000 CPH (optimum). The 3 main systems are:

-

SM471 (Higher Speed)

- SM481 (Balance of Speed vs

Cost)

-

SM482 (Budget Conscious)

We invite you to

consider the Samsung SMT placement equipment for your placement requirements.

We are confident that you will find the equipment to be well designed, robust

and very intuitive and efficient, thus allowing you to be more efficient with

your process and to keep up with the demands of your process.

Samsung also offers a

variety of feeder solutions, including their Auto-Loading, Auto-Splicing and

Auto-Stripping SMART Feeders.

Managing your feeders can often be a

dedicated task requiring the continuous commitment of personnel to ensure that

the reels never run out of components. With Samsung's SMART Feeders you

can attach a 2nd reel to a feeder and when the 1st reel is exhausted the feeder

will automatically load, splice and transfer to the 2nd reel, thus allowing you

more time to focus on other tasks.

We encourage you to talk with us about

the wide variety of feeder options available for the Samsung SMT Placement

Equipment.